Self-lubricating bushings are specially engineered components that reduce friction without the need for additional oil or grease. But what exactly makes them “self-lubricating”? The answer lies in the materials.

Different applications demand different performance characteristics—such as high load, chemical resistance, or low noise. That’s why material selection is key when choosing the right bushing.

Common Materials in Self-Lubricating Bushings

Here’s a breakdown of the most commonly used materials and their key advantages:

Bronze (Oil-Impregnated Bronze)

Used for: Heavy-duty applications, high loads, and high temperatures.

- Composition: Porous bronze matrix filled with lubricating oil.

- Benefits:

- Excellent wear resistance

- Long service life

- Can operate under high load and speed

- Applications: Die sets, presses, industrial robots, CNC machinery

Related:

self lubricating bronze bushing, bronze self lubricating bushings

Brass

Used for: Low to moderate loads, precision applications.

- Often combined with: Solid lubricant inserts (like graphite).

- Benefits:

- Good machinability

- Corrosion resistance

- Suitable for custom shapes

- Applications: Molds, automation systems, packaging machines

Related:

self lubricating brass bushing, self lubricating brass

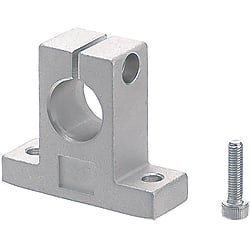

Composite Type Bushings

Structure:

- Steel backing

- Sintered bronze intermediate layer

- PTFE or polymer-based sliding surface

- Benefits:

- High load capacity

- Low friction coefficient

- Maintenance-free under dry conditions

- Applications: Automotive, construction equipment, injection molding

Related:

du self lubricating bushing

Plastic (Polymer-Based Materials)

Brands: IGUS®, GGB®, custom OEMs

- Materials include: POM, PA, PTFE, UHMWPE, and composites

- Benefits:

- Lightweight

- Quiet operation

- Resistant to chemicals and moisture

- Applications: Food processing, printers, packaging equipment

Related:

self lubricating plastic bushing

How to Choose the Right Material?

| Application Condition | Recommended Material |

|---|---|

| High load & high temp | Bronze, DU |

| Corrosive environment | Brass, Plastic |

| Clean or dry setup | Plastic, DU |

| Precision guiding | Brass, DU |

Frequently Asked Questions

Q: Is bronze better than brass for bushings?

A: Bronze generally offers better load capacity and wear resistance, but brass is easier to machine and ideal for lighter-duty applications.

Q: Can plastic bushings handle industrial loads?

A: Yes—advanced polymers like IGUS® materials can handle surprising loads with proper design.

Q: Are DU bushings really maintenance-free?

A: Absolutely. They’re designed for dry operation, especially under oscillating or rotating motion.

Conclusion

From bronze and brass to plastic, self-lubricating bushings come in a variety of materials tailored for different environments and requirements. Understanding these materials helps you select the best fit for your application