Ball Screw Structure and Working Principle

A ball screw is a mechanical device that converts rotary motion into linear motion, or vice versa. It consists of three main components:

- Ball screw shaft – a precision-threaded shaft

- Ball nut – a nut with an internal ball return system

- Balls – steel balls circulating between the shaft and nut

The rolling motion of the balls greatly reduces friction, providing high transmission efficiency and precise linear motion. Ball screws are widely used in CNC machines, robotics, and industrial automation.

Slenderness Ratio of Ball Screws

The slenderness ratio is defined as the ratio of the screw shaft length to its diameter. It plays a critical role in the accuracy and stability of the system.

- For single-start ball screws running at 1500–2000 rpm, the recommended slenderness ratio should not exceed 60.

- For dual-start (left-right hand) screws, the ratio should not exceed 40.

Risks of excessive slenderness ratio:

- Decreased positioning accuracy

- Increased risk of resonance and vibration

- Shortened lifespan or even shaft deformation at high speeds

While these recommended values are based on past engineering experience, higher speeds or complex operating conditions require precise calculations using critical speed formulas to determine allowable diameter, load, and expected life.

Ball Screw Noise Levels

Ball screws inevitably generate noise during operation. The noise level varies depending on manufacturing process and accuracy class.

At a typical speed range of 1500–2000 rpm under permissible load:

- C10 rolled screws: noise exceeds 80 dB

- C7 rolled screws: around 75 dB

- C5 ground screws: approximately 60 dB

How to reduce noise:

- Use higher-precision (C5 or above) or ground ball screws

- Select a larger lead to achieve the same linear speed with lower rotation speed

- Avoid overloading and overspeeding

These strategies help achieve smoother motion and a quieter working environment.

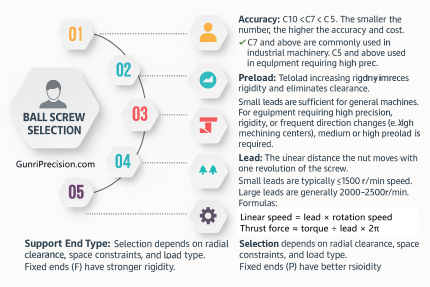

Ball Screw Selection

01.Accuracy

Ball screw accuracy grades are ranked as: C10 < C7 < C5 < C3

The lower the number, the higher the precision and cost.

- ✅ C7 and above are commonly used in general industrial machinery.

- ❗C5 and above are preferred for high-precision applications such as CNC machines.

- 💡On average, C7 screws cost 2–3 times less than C5 screws, making them more economical for standard tasks.

02. Preload

Preload increases rigidity and eliminates axial clearance. The level of preload depends on the machine’s application.

- Light preload: suitable for general-purpose equipment.

- Medium to high preload: required for applications with high precision demands, frequent directional changes, or higher stiffness—e.g., CNC machining centers.

⚠️ Note: Higher preload increases required torque and may reduce ball screw service life due to added internal stress.

03. Lead

Lead refers to the linear distance the nut moves per one screw revolution.

- Small leads (e.g. 2–5 mm): suitable for applications requiring high thrust and lower speed (≤ 1500 rpm).

- Large leads (e.g. 10 mm+): used for high-speed movement (typically 2000–2500 rpm).

Common equations:

Linear Speed = Lead × Screw RPMThrust Force ≈ Torque ÷ (Lead × 2π)Resolution = Lead ÷ Step Angle × Motor Step Size

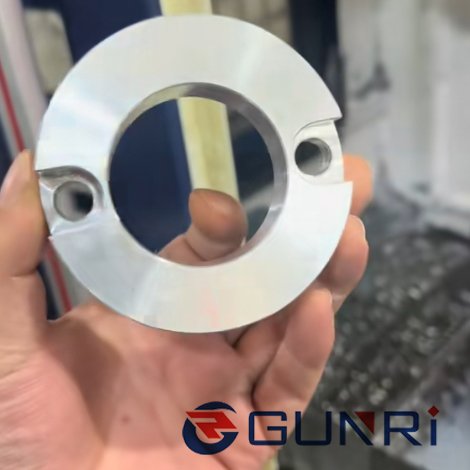

04. Length

The required ball screw length includes both the total length and the effective travel.

- Effective travel = Stroke + ½P (preload allowance) + margin

- Common materials: carbon steel or stainless steel

Typical diameter × lead combinations:

- d10×P2, d12×P4, d16×P5

- d20×P5, d20×P10

- d25×P5, d25×P10

- d32×P10

05. Support End Types

The selection of support end type depends on:

- Required rigidity

- Radial clearance

- Installation space

- Load direction

Types:

Floating support (P): allows smoother rotation, useful in systems with minor axial displacement

Fixed support (F): provides high rigidity, ideal for precision applications

Conclusion

When selecting a ball screw, it’s important to evaluate more than just size and cost. A solid understanding of the ball screw structure, slenderness ratio, and noise characteristics ensures reliable performance and extended service life.