Showing 33–48 of 373 results

-

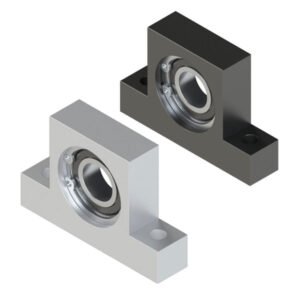

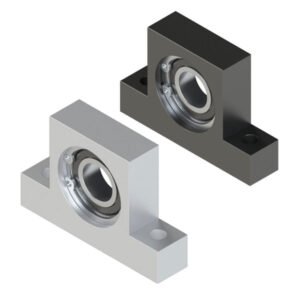

Bearing seat material: S45C, SUS304, A2017 Surface treatment: black / nickel plating, natural color anodized Bearing material: steel, stainless steel Inner diameter: 3~12mm Bearing seat height: 10~40mm

-

Bearing seat material: S45C, SUS304 Surface treatment: black, nickel plating Bearing material: steel, stainless steel Inner diameter: 8~20mm Bearing seat height: 15~35mm

-

Bearing seat material: aluminum alloy Surface treatment: natural color anodized Bearing material: steel Inner diameter: 8~15mm Bearing seat height: 20~50mm

-

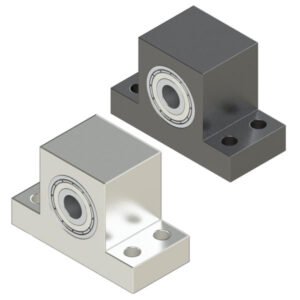

Bearing seat material: S45C, SUS304, A2017 Surface treatment: black, nickel plating, natural color anodizing Bearing material: steel, stainless steel Inner diameter: 3~40mm Bearing seat height: 10~100mm

-

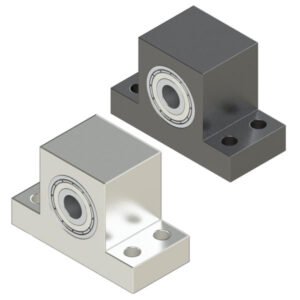

Bearing seat material: S45C, SUS304, A2017 Surface treatment: black, nickel plating, natural color anodizing Bearing material: steel, stainless steel Inner diameter: 3~30mm Bearing seat height: 10~80mm

-

Side plate installation: Internal thread

Part installation method: External thread shape: Hexagonal type

Material: S45C, SUS304

Surface treatment: Blackening, Nickel plating

-

Side plate installation: Internal thread

Part installation method: External thread shape: Standard type

Material: S45C, SUS304

Surface treatment: Blackening, Nickel plating

-

Side plate installation: Internal thread

Part installation method: External thread shape: Stepped type

Material: S45C, SUS304

Surface treatment: Blackening, Nickel plating

-

Side plate installation: Internal thread

Part installation method: Internal thread shape: Hexagonal type

Material: S45C, SUS304

Surface treatment: Blackening, Nickel plating

-

Side plate installation: Internal thread

Part installation method: Internal thread shape: Standard type

Material: S45C, SUS304

Surface treatment: Blackening, Nickel plating

-

Side plate installation: Internal thread

Part installation method: Internal thread shape: Stepped type

Material: S45C, SUS304

Surface treatment: Blackening, Nickel plating

-

Side plate installation: Internal thread

Part installation method: Circlip shape: Hexagonal type

Material: S45C, SUS304

Surface treatment: Blackening, Nickel plating

-

Side plate installation: Internal thread

Part installation method: Circlip shape: Standard type

Material: S45C, SUS304

Surface treatment: Blackening, Nickel plating

-

Side plate installation: Internal thread

Part installation method: Circlip shape: Stepped type

Material: S45C, SUS304

Surface treatment: Blackening, Nickel plating

-

Side plate installation: External thread

Part installation method: Internal thread shape: Hexagonal type

Material: S45C, SUS304

Surface treatment: Blackening, Nickel plating

-

Side plate installation: External thread

Part installation method: Internal thread shape: Standard type

Material: S45C, SUS304

Surface treatment: Blackening, Nickel plating