What Is a Self-Lubricating Bushing?

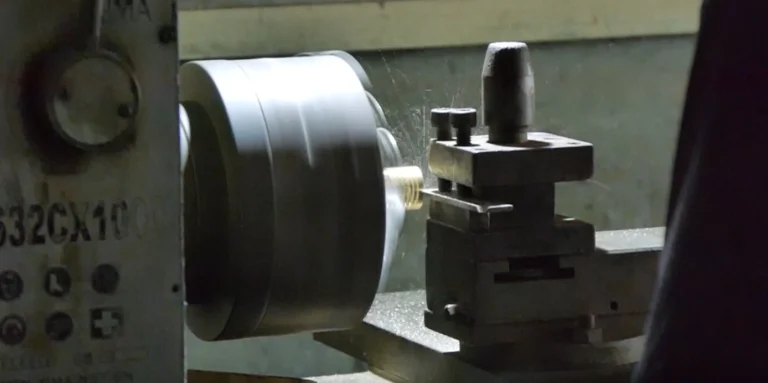

A self-lubricating bushing is a type of bearing component designed to reduce friction between moving parts without the need for external lubrication. Unlike conventional bushings that require regular oil or grease, these bushings contain built-in lubricants—such as graphite, PTFE, or oil-impregnated metals—that are released gradually during operation.

They are widely used in industries such as automotive, mold tooling, automation, packaging, and heavy machinery, offering long-term, maintenance-free performance.

How Does a Self-Lubricating Bushing Work?

The secret lies in the material composition and internal structure.

- Metal-based bushings (e.g. bronze, brass, DU bushings) often include tiny pores filled with lubricating oil or solid lubricant particles.

- Plastic-based bushings (like those from IGUS) are engineered with low-friction materials such as PTFE or POM.

When the shaft begins to rotate, heat and motion activate the lubricant, allowing it to migrate to the surface. This forms a thin film that:

- Reduces wear

- Minimizes friction

- Prevents metal-to-metal contact

Over time, this self-lubricating effect replenishes itself through either continued release or redistribution of the embedded lubricant.

What Are the Benefits?

✅ Maintenance-Free Operation

No need for oiling or greasing—ideal for hard-to-reach places.

✅ Extended Service Life

Reduced friction means lower wear and longer uptime.

✅ Clean and Eco-Friendly

No oil leaks, making them suitable for cleanrooms or food processing.

✅ Consistent Performance

Stable coefficient of friction over a wide temperature range.

Common Applications

- Injection molds and stamping dies

For guide posts, wear plates, and slides. - Automotive components

Suspension systems, pedals, door hinges. - Industrial automation

Robots, conveyors, and motion control equipment. - Office and household appliances

Printers, sliding drawers, and fans.

Frequently Asked Questions

Q: Can you add oil to a self-lubricating bushing?

A: Typically not necessary. In fact, adding oil can wash away embedded lubricants or cause buildup.

Q: Do they work in high-load applications?

A: Yes—DU bushings and bronze variants are designed for high-load and high-speed environments.

Q: What temperatures can they withstand?

A: Depending on the material, most self-lubricating bushings work in -40°C to 250°C ranges.

Conclusion

Self-lubricating bushings are a smart solution for reducing maintenance, minimizing downtime, and improving mechanical efficiency. Their ability to “lubricate themselves” makes them especially valuable in demanding industrial settings.