Precision alignment is the foundation of high-performance molds, CNC fixtures, and automated equipment. DIN 7979 tapped dowel pins are one of the unsung heroes in these applications, offering repeatable, load-resistant positioning with easy removal. But not all dowel pins are the same—and sourcing the right specification requires more than just looking at the diameter and length.

In this article, we provide industrial buyers and engineers with a practical guide to DIN 7979 pins, including sizing, interference fits, tolerance selection, and real-world use cases across the mold, CNC machining, and automation industries.

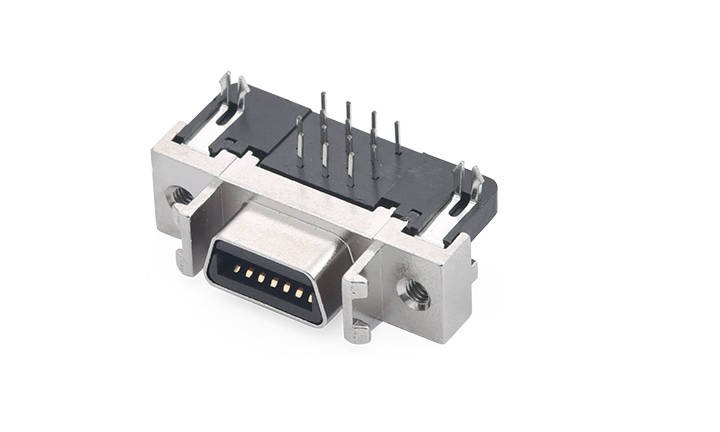

What Are DIN 7979 Tapped Dowel Pins?

DIN 7979 pins are precision cylindrical locating pins with internal threads on one end for extraction or pulling. Unlike plain dowel pins (DIN 6325), the tapped design simplifies maintenance and disassembly—particularly in mold base alignment or robotic tooling plates.

Key Specifications:

- Material: Hardened steel (commonly HRC 58–62), stainless steel optional

- Tolerance: m6 standard fit

- Ends: One end chamfered, other end tapped for threaded puller

- Size range: Ø3mm–Ø20mm, lengths up to 120mm

They’re typically installed with light to medium interference fit, often paired with reamed holes for maximum alignment precision.

Applications in Mold Making: Repeatability Without Rework

In the plastic injection mold industry, precision alignment between mold base components is critical. DIN 7979 pins are commonly used between the A-plate and B-plate, especially in high-cavity molds where even a 0.01 mm misalignment can cause flash or reject rates.

Use Case:

A Thai mold factory producing multi-cavity consumer product molds adopted DIN 7979 pins to replace standard cylindrical pins. The internal thread allowed for faster disassembly during maintenance without damaging expensive mold bases. Their production team reported a 35% reduction in tool downtime thanks to easier pin removal.

Why DIN 7979 over DIN 6325?

The tapped design adds cost but delivers long-term savings in complex tools that require regular maintenance or disassembly.

CNC Fixtures: Aligning Workholding with Consistency

In CNC machine shops, repeatable workholding is the key to reducing cycle times and improving dimensional accuracy. DIN 7979 pins are widely used to align base plates, sub-plates, and custom fixtures.

Practical Tip:

Use m6 tolerance fit in steel or aluminum fixtures. Ream holes to H7 tolerance for best press-fit compatibility. Avoid over-pressing—use thermal shrinking or hydraulic press when required.

Use Case:

A German aerospace machining supplier standardized on DIN 7979 pins for their modular tombstone setups. Each tombstone features replaceable fixtures aligned with 7979 pins and secured with clamps. By using tapped pins, the team could quickly lift out worn fixtures for replacement without disturbing the main base, maintaining alignment within 10 microns.

Regional Standards & Fit Considerations: DIN vs. ANSI

While DIN 7979 is a European standard, many buyers in North America and Southeast Asia use mixed standards. For example, U.S. customers often reference ASME B18.8.2 pins, which differ in tolerances and material spec.

Practical Insight for Sourcing:

- EU & Asia: DIN 7979 is widely adopted, with suppliers offering full metric sizes and heat treatment.

- USA: May need to clarify tapped hole size and metric-to-inch conversion if ordering from overseas.

- Japan: Equivalent JIS standards are less common—many automation firms still use DIN pins for imported European tooling compatibility.

Pro Tip:

Clarify if your supplier provides m6 class tolerances as standard, especially when sourcing from Chinese manufacturers. Lower-grade pins with unverified tolerance can cause misalignment and wear in precision applications.

Sourcing from China: What Engineers Should Ask Before Buying

China is a leading exporter of DIN-standard pins, but not all factories are equal. For buyers in mold or CNC industries, precision and repeatability trump cost savings. Here’s what experienced sourcing managers recommend checking:

Checklist for Buyers:

- Heat Treatment Certification: Confirm HRC rating and depth of hardening.

- Tolerance Guarantee: Ask for m6 fit test data or sample reports.

- Material Traceability: Request steel origin (commonly SUJ2 or equivalent).

- Thread Quality: Poorly tapped threads cause issues during pin removal. Ask for go/no-go gauge testing.

- Batch Consistency: Request dimensional inspection report per lot.

Use Case:

An Indian automation integrator ordered DIN 7979 pins for a robotic arm tooling plate from a low-cost supplier. The first batch had poor fit consistency and cracked during press-fit. After switching to a certified supplier offering 100% inspection and heat treatment reports, they reduced failure rate to near zero—saving both rework time and reputation.

FAQs About DIN 7979 Tapped Dowel Pins

Q1: Can I reuse DIN 7979 pins after removal?

A: Yes, if the interference fit isn’t too aggressive and the pin surface isn’t damaged. Inspect for wear or scoring before reuse.

Q2: What thread type is used in DIN 7979?

A: Metric thread, commonly M4 to M12 depending on pin diameter. Confirm with your supplier for exact spec.

Q3: Is stainless steel available for DIN 7979 pins?

A: Yes, stainless versions are available for corrosion-sensitive environments like food automation or cleanrooms.

Q4: What’s the difference between DIN 7979 and DIN 6325?

A: DIN 7979 has a tapped end for removal, while DIN 6325 is a plain cylindrical pin used where disassembly isn’t needed.

Q5: How do I remove a tight-fit DIN 7979 pin?

A: Use a threaded puller bolt in the tapped hole and apply steady force. Avoid hammering to prevent misalignment.

Get a Quote or Request Free Samples

As a trusted Chinese manufacturer specializing in precision dowel pins for mold, CNC, and automation applications, we understand the importance of reliability, consistency, and fit. Whether you’re sourcing DIN 7979 pins for a new tool build or upgrading old fixtures, we offer competitive pricing, fast lead times, and full dimensional reports.

Contact us today to request a quote or free sample—we’re here to support your alignment needs with precision parts that perform under pressure.