Both locating pins and dowel pins are common fastening and positioning components in mechanical assemblies, but they differ in purpose, design, and function.

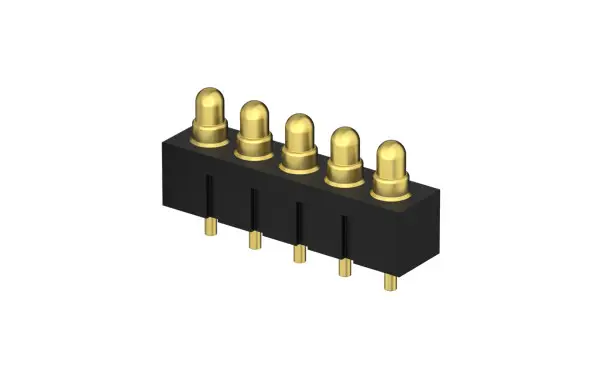

Locating Pins

Main Function

- Accurate positioning: Locating pins are mainly used to ensure precise alignment of parts during assembly, preventing displacement during operation.

- Repeatability: They ensure consistent positioning in cases of repeated assembly and disassembly.

Design Features

- High precision: Locating pins are manufactured to tighter tolerances to achieve accurate positioning.

- Various types:

- Cylindrical locating pins: standard cylindrical shape for general positioning.

- Tapered locating pins: conical tip for easier alignment and insertion.

- Slotted locating pins: with a longitudinal slot, allowing compression for interference fits.

- Threaded locating pins: with threads for locking in place.

- Double-ended locating pins: different diameters or shapes at each end for special requirements.

Applications

- High-precision assembly: such as mold making, precision machinery, and electronics assembly.

- Frequent disassembly: where parts must be repeatedly installed and removed with consistent accuracy.

Dowel Pins

Main Function

- Joining and fastening: Dowel pins are primarily used to connect and secure two or more parts, maintaining their relative position.

- Load transfer: In some cases, dowel pins transmit torque or shear forces.

Design Features

- Simple structure: Usually plain cylindrical shape, easy to manufacture.

- Various materials: Can be made from steel, stainless steel, aluminum, plastics, etc.

- Standardized: Available under ISO, DIN, GB, and other specifications.

Applications

- General mechanical assembly: fixing shafts and parts in machinery.

- Low precision requirements: suitable where positioning accuracy is not critical.

Key Differences

- Function:

- Locating pins → precise positioning, ensuring assembly accuracy and repeatability.

- Dowel pins → fastening and holding parts together, transmitting forces.

- Accuracy:

- Locating pins: tighter tolerances, higher precision.

- Dowel pins: lower precision, simpler installation.

- Design complexity:

- Locating pins: more complex, available in multiple variations.

- Dowel pins: simple cylindrical design.

- Application scenarios:

- Locating pins: high-precision assemblies, frequent disassembly.

- Dowel pins: general mechanical connections, standard fastening.

Examples

Locating Pin Applications

- Mold alignment: ensures the upper and lower mold halves are precisely aligned during every closing cycle.

- Precision machinery: maintains positional accuracy of parts to avoid assembly errors that could cause failures.

Dowel Pin Applications

- Mechanical connections: fixing shafts and components in machinery for stability in transmission systems.

- Furniture assembly: securing wooden panels and connectors for structural stability.

By understanding these distinctions, it becomes clearer how locating pins and dowel pins serve different roles in mechanical assemblies. Choosing the correct type of pin improves assembly quality and equipment performance.

This content is a technical overview compiled by GUNRI Automation Parts as a knowledge introduction to “locating pins.” We hope it helps users across industries better understand our products and make the right selection. For further inquiries or product consultation, feel free to contact GUNRI.