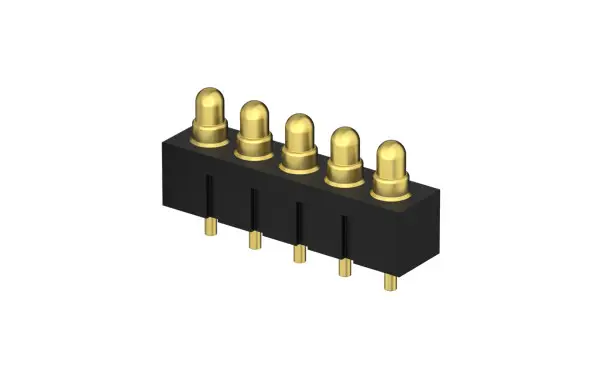

The core working principle of a probe plug connector lies in the compression and rebound mechanism of the internal spring inside the contact pin (also known as a pogo pin). This dynamic adjustment capability enables the connector to maintain optimal working height and enhances the contact pressure between electrical contacts. As a result, it ensures a secure and reliable electrical connection, effectively minimizing the risk of poor contact or disconnection caused by vibration or shock, and safeguarding continuous signal transmission.

The performance of a probe connector is closely tied to the design of its contact pin structure, and different types of pin structures bring varying advantages to specific application scenarios.

- Flat-bottom pins feature a flat design at the base of the barrel, offering excellent stability. They allow for precise soldering onto PCB boards, reducing the likelihood of alignment errors during assembly.

- Plug-in base pins are equipped with a built-in positioning pin at the bottom of the barrel. This enhances soldering accuracy and effectively prevents misalignment during mounting.

- Double-ended pins offer greater spatial flexibility. This type of connector is well-suited for board-to-board connection scenarios, meeting the demands of increasingly complex internal layouts in modern electronic devices.

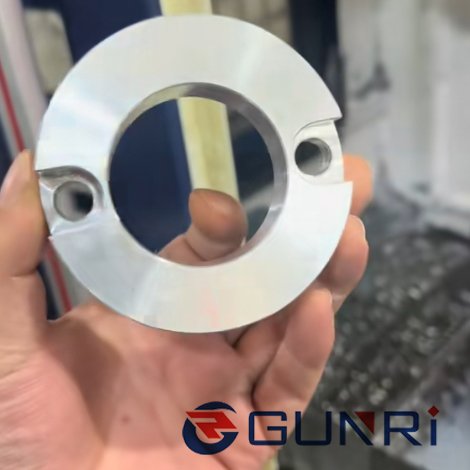

Currently, the probe components produced by GUNRI have become critical parts in a wide range of smart and consumer electronics, including Bluetooth earphones, smart wristbands, smartwatches, and drones. Thanks to their excellent electrical connectivity and structural adaptability, these connectors provide strong support for the stable operation of these intelligent devices.