What Is a Self-Lubricating Bushing?

A self-lubricating bushing is engineered to reduce friction and wear without the need for external oil or grease. It contains solid or liquid lubricants that are either embedded in the material or housed in tiny pores within the bushing structure.

These bushings are ideal for applications where maintenance access is difficult or where consistent, long-lasting performance is critical—such as in mold bases, automation systems, and automotive components.

Should You Add Lubrication?

In most cases, no—you should not add oil or grease to a self-lubricating bushing.

Here’s why:

❌ Why External Lubrication Is Not Recommended:

- Disruption of built-in lubrication

Oil or grease can flush out the embedded lubricant in porous metal or composite materials, damaging the self-lubricating mechanism. - Attracts dirt and contaminants

Grease acts like a magnet for dust and debris, leading to abrasion and premature wear. - Creates buildup or slippage

Especially in dry-running designs (e.g., plastic/PTFE bushings), external lubrication can cause sliding inconsistencies or clogging.

When Is Lubrication Acceptable?

There are rare cases where adding a light lubricant might help—but only if the manufacturer explicitly recommends it:

- During initial break-in period for certain sintered bronze bushings

- Extreme loads or high speeds, where additional lubrication might extend lifespan temporarily

- Replenishing oil-impregnated bushings after long idle periods

In such cases, use only lightweight machine oil, not heavy grease.

How to Know If Your Bushing Is Truly Self-Lubricating

Check for these signs:

- Product label includes terms like “self-lubricating,” “oil-impregnated,” “DU,” or “dry-running”

- No grease fittings or lubrication ports

- Manufacturer documentation states “maintenance-free” or “no lubrication required”

Brands like IGUS, SKF, and MISUMI clearly indicate this in their product datasheets.

Frequently Asked Questions

Q: What happens if I grease a self-lubricating bushing?

A: It can degrade performance, attract dust, and wash out the built-in lubricants.

Q: Can I use WD-40 on my bushing?

A: No. WD-40 is a solvent, not a lubricant—it may strip away protective coatings.

Q: Are there exceptions for high-speed machinery?

A: Some high-performance bushings allow a secondary lubrication layer, but only if specified.

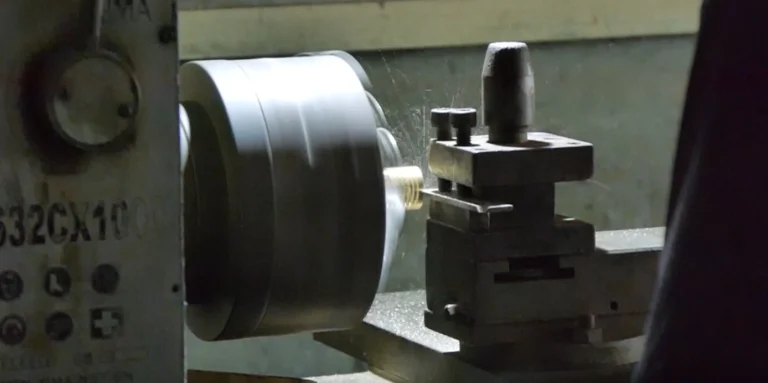

Install self-lubricating bushings on the mold

Conclusion

Self-lubricating bushings are designed to be maintenance-free. In most situations, adding external lubrication will do more harm than good. When in doubt, always consult the manufacturer’s guidelines.